The Use of Immersion Heater in the Nuclear Power and Oil Pipeline Industry

Have you ever wondered how we maintain the right temperature in large industries? Instead of thinking about simple tasks, we’re looking at how crucial systems like oil pipelines and nuclear power plants stay at the correct temperature.here is the useage of immersion heater.

In this article, we’ll look at how immersion heaters are essential to maintaining everything in working order. These heaters are essential for managing temperatures effectively and safely. Let’s dive in and discover how these important tools work and why they matter.

How Does Nuclear Power Generate Heat and Electricity?

Nuclear power plants generate heat and electricity through a process called nuclear fission. In this process, the nucleus of an atom splits into smaller parts, releasing a large amount of thermal energy. This heat is used to convert water into steam. The steam then drives a turbine connected to an electrical generator, turning thermal energy into electricity.

Immersion heater play a vital role in this process. They help maintain the optimal temperatures required for efficient heat generation and prevent issues that could arise from temperature fluctuations. By ensuring the water in the reactor remains at the right temperature, immersion heater contribute to the smooth operation of the plant and the safe production of electricity.

Essential Factors of Nuclear Energy of immersion heater

Nuclear energy is an important source of electricity, providing around 14% of the world’s power. Despite its efficiency and low greenhouse gas emissions, nuclear energy requires strict safety measures. The processes involved in nuclear fission and turbine operation must be carefully managed to avoid any hazards.

Control systems and monitoring devices, such as thermocouples and control panels, are essential in this environment. These tools work alongside immersion heaters to ensure the safe and efficient operation of nuclear power plants, maintaining the correct temperature and preventing potential issues.

The Role of Immersion Heaters in the Nuclear Power Industry

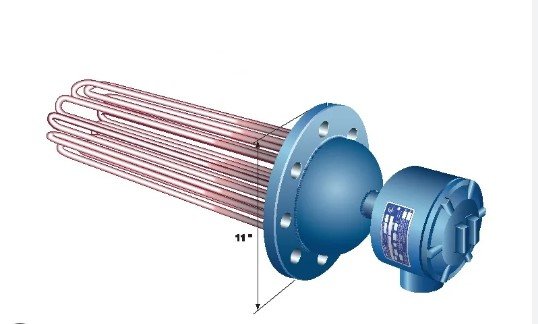

Nuclear power plants need to maintain precise temperatures to ensure safety and efficiency. Any deviation from the optimal temperature can lead to serious problems. Immersion heaters play a crucial role in regulating these temperatures. In this section, we’ll examine how immersion heaters support nuclear power plants’ safe and efficient functioning.

Efficient Temperature Control in Pressurizers of immersion heater

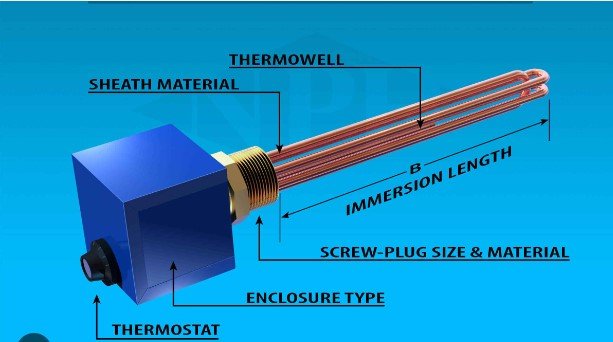

Immersion heaters play a critical role in maintaining the temperature and pressure within pressurizers in nuclear power plants. These heaters are essential for ensuring that the primary coolant, which is water, remains in a liquid state even at high temperatures of up to 321°C (610°F).

The heaters are installed at the bottom of the pressurizer tank, where they help to manage the pressure by heating the water to generate steam when necessary. This process is crucial for controlling the overall pressure in the reactor loop and preventing the coolant from boiling.

Maintaining System Stability of immersion heater

In a pressurized water reactor, immersion heaters help to keep the system stable by regulating the temperature and pressure. The heaters are activated when sensors detect a drop in pressure, heating the water and converting it to steam to increase the pressure.

This precise control helps to avoid pressure fluctuations that could affect the reactor’s performance. Conversely, if the pressure exceeds the desired level, cool water is introduced to lower the temperature and pressure, maintaining the reactor’s stability and efficiency.

High-Performance Materials

Immersion heaters used in nuclear power plants are designed to handle extreme conditions. Stainless steel is commonly used for heating elements due to its resistance to corrosion and high-temperature strength.

This material is well-suited for the harsh environment of a pressurizer, where it must withstand both high pressure and temperature, as well as continuous exposure to radiation. Additionally, materials like Incoloy and Inconel are used for their durability and ability to perform under high-wattage applications, further enhancing the heater’s effectiveness in maintaining reactor stability.

Ease of Maintenance

One of the advantages of immersion heaters is their ease of maintenance. If something goes wrong, it’s possible to fix specific broken parts without having to replace the heater as a whole.

This not only simplifies the maintenance process but also reduces radiation exposure for maintenance workers as the pressurizer’s operational life is extended. The ability to replace elements through simple cutting and welding also contributes to the economic efficiency of using immersion heaters in nuclear power plants.

What are the Common Challenges in Oil Pipelines of immersion heater

Nowadays?

Oil pipelines face major challenges in cold climates, primarily due to wax build-up. As crude oil cools during transport, paraffin wax and other hydrocarbons can solidify, creating a thick layer inside the pipeline. This wax can block the flow of oil, making it harder for the pipeline to work efficiently.

Removing these obstructions requires regular maintenance, which is both time-consuming and costly. Wax build-up not only reduces the pipeline’s capacity but also increases the risk of operational issues and potential damage to the infrastructure.

Another significant challenge is freezing, especially in very low temperatures. As oil cools, it can become thick or freeze, leading to severe flow restrictions or complete blockages. Water in the oil can also turn into ice, worsening the problem.

To prevent freezing, additional heating systems and insulation are needed to keep the oil fluid. These solutions add to operational costs and complexity, making it crucial for pipeline operators to invest in effective temperature management to ensure smooth and continuous oil transport.

How Immersion Heater Benefit the Oil Pipeline Industry?

Here, we’ll explore how these heaters help keep oil flowing smoothly and safely in pipelines.

Preventing Fluid Solidification of immersion heater

In the oil pipeline industry, immersion heaters play a critical role in preventing oil from solidifying under extremely cold conditions. When temperatures drop significantly, oil can turn into a gel-like substance or wax, which can obstruct the flow and cause operational issues.

To address this, immersion heaters are installed on the side of storage tanks or pipelines. This setup does not require alterations to the existing infrastructure and ensures that the oil remains fluid. By maintaining the oil at a temperature above its solidification point, these heaters help prevent blockages and ensure smooth flow through the pipeline system.

Facilitating Oil Transport of immersion heater

During the refining process, crude oil must be heated to reduce its viscosity before it can be fractionated. Immersion heaters can heat the crude oil to the optimal temperature for the process. By doing so, the heaters make the oil less viscous, which facilitates its smooth and efficient flow to the furnace.

This heating is crucial for ensuring that the oil moves rapidly and effectively through the refining process, minimizing delays and operational costs. Proper heating helps maintain the efficiency of the refinery and supports the overall productivity of oil processing.

Heating Oil in Pipelines of immersion heater

Oil pipelines, especially those transporting oil over long distances, rely on immersion heaters to ensure the oil remains at the right temperature for smooth transport. As oil travels through pipelines, it can cool down and become more viscous, leading to potential flow issues.

Immersion heaters can strategically place within the pipeline system to maintain the oil at a temperature that ensures optimal flow. This heating helps prevent blockages and keeps the oil moving efficiently through the pipeline, thus improving the overall effectiveness and reliability of the transportation system.

Maintaining Lubrication Oils of immersion heater

In the oil pipeline industry, lubrication oils are essential for maintaining the performance of heavy machinery and gearboxes used in refineries. These oils need to be kept at specific temperatures to ensure they remain effective as lubricants. An immersion heater can install in a tank containing lubricating oil to maintain it at the desired temperature.

Immersion heaters contribute to adequate lubrication and smooth functioning of machinery by maintaining the oils heated, which lowers wear and tear and maintenance requirements. Maintaining the longevity and effectiveness of refinery equipment depends on this temperature regulation.

Heating Chemicals of immersion heater

The oil pipeline industry often involves the use of a variety of chemicals that require heat for processing. Immersion heaters can heat these chemicals such as acetone, barium hydroxide and other substances required for different chemical engineering processes.

The efficient heating provided by immersion heater ensures that these chemicals reach the necessary temperatures for their intended applications. This capability makes immersion heater a valuable tool in the petroleum industry, where precise temperature control is crucial for effective chemical reactions and processing.

Here’s how to make your cartridge heater last longer!

Where to Find the Best Immersion Heater for Nuclear Power and Oil Pipelines

Immersion heater play a key role in keeping everything at the right temperature in nuclear power plants and oil pipelines. These heaters are crucial for maintaining safety and efficiency. But where can you find the best immersion heaters for these industries?

HASTECO is a top choice for high-quality immersion heaters. They offer a wide range of heaters designed for tough environments, including nuclear power and oil pipelines. HASTECO is known for its excellent products, which are built with the best materials and designed by skilled engineers. They provide reliable solutions that ensure your systems run smoothly and safely.

If you’re looking for the best immersion heaters to meet your needs, HASTECO is the place to go. They offer great products and helpful support to make sure you get the right heater for your industry.

Wrapping It Up!

Immersion heaters are very important in the nuclear power and oil pipeline industries. They keep everything at the right temperature, making sure processes are safe and work well. As technology improves, these heaters will continue to be vital in these fields.

Want to see how immersion heater can make a difference for you? Get in touch with HASTECO to see how their knowledgeable solutions can maintain the efficiency of your business.