Welcome, readers! Today, we’re diving into the world of circulation heaters and learning how to accurately calculate their KW (kilowatt) requirements. Understanding the KW requirements is essential for ensuring efficient and effective heating. Let’s explore the basics of circulation heaters and the significance of accurate calculations.

What is the KW requirement?

KW requirements refer to the number of kilowatts (kW) of power a circulation heater needs to meet the desired heating output. It represents the power capacity necessary for the circulation heater to provide the required heat to raise the temperature of the fluid flowing through it by a specified amount. Accurately calculating the KW requirements ensures that the circulation heater is appropriately sized and capable of delivering the necessary heat output for a given application.

What are the circulation heaters?

Now that we’ve laid the groundwork let’s delve deeper into circulation heaters. This section explores their definition, working principle, and the components that make them tick. Click here to learn more about it.

Definition and Working Principle

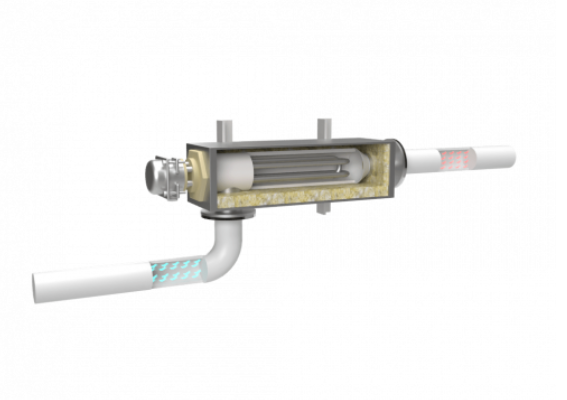

At its core, a circulation heater is a device designed to heat fluids as they flow through a closed-loop system. It operates on a straightforward principle: as the fluid passes through the circulation heater, it comes into contact with a heating element, which raises its temperature to the desired level. The heated fluid continues its journey through the system, ready for its intended application.

The heating element in a circulation heater can take various forms, such as electric coils, immersion heaters, or finned tubular components. These elements are strategically placed to maximize heat transfer and ensure efficient heating. By leveraging the heat generated by the component, circulation heaters can achieve rapid and precise temperature control.

Components and Types of Circulation Heaters

To better understand circulation heaters, we must familiarize ourselves with their key components. While specific designs may vary, most circulation heaters consist of the following elements:

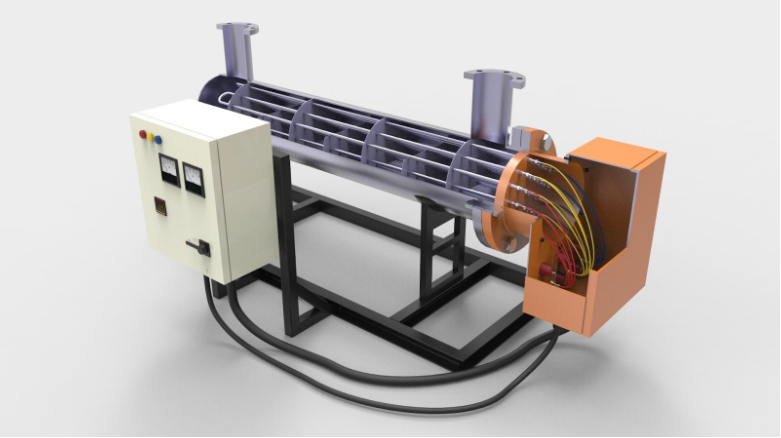

- Heating Element. As mentioned, the heating element generates the heat required to raise the fluid’s temperature. It is carefully designed to optimize heat transfer and ensure efficient performance.

- Vessel or Housing. This is the container that encloses the fluid being heated. It is designed to withstand the pressure and temperature conditions of the system while providing insulation to minimize heat loss.

- Control Panel. The control panel allows users to monitor and adjust the operating parameters of the circulation heater. It typically includes temperature controllers, power switches, and safety mechanisms.

Now, let’s explore the types of circulation heaters commonly found in various industries.

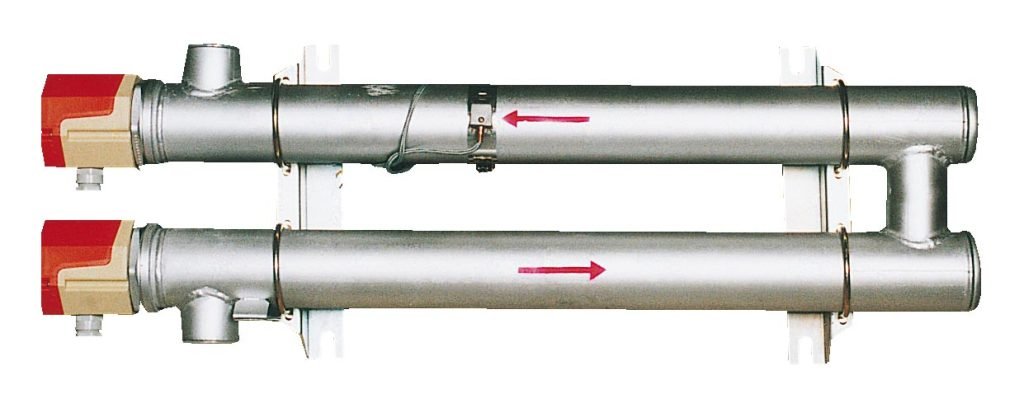

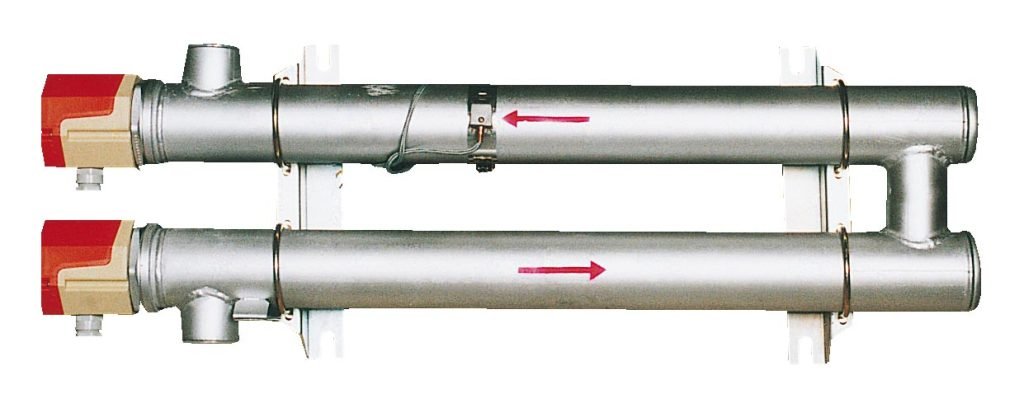

- Inline Circulation Heaters. These heaters are installed directly in the fluid flow path, allowing efficient and continuous heating. They are often used when rapid heating or maintaining a constant temperature is crucial.

- They have flanged Circulation Heaters. Flanged heaters are designed to be mounted on the side of tanks or vessels. They are commonly used for heating large volumes of fluids in industrial settings, such as oil storage tanks or chemical processing vessels.

- Over-the-Side Circulation Heaters. These heaters are designed to be immersed from the top into the fluid, typically using a bracket or a flange. They are commonly used when installing heaters directly into the tank or vessel is impractical or challenging.

By understanding the different components and types of circulation heaters, you can gain insight into their inner workings and choose the most suitable type for your heating requirements.

What is the connection between them?

Circulation heaters are devices used to heat fluids as they pass through a closed-loop system. They have various applications in manufacturing, oil and gas, and commercial settings. Calculating the KW requirements precisely ensures the heater is appropriately sized and capable of delivering the desired heat output.

Accurate KW calculations strike a balance between efficiency and effectiveness. Underestimating the requirements could result in inadequate heating while overestimating leads to unnecessary energy consumption and increased costs. By determining the proper KW requirements, you can optimize the performance of your circulation heater.

Join us as we unravel the intricacies of circulation heaters and guide you through calculating their KW requirements.

Factors Affecting KW Requirements

Now that we have a solid understanding of circulation heaters, let’s explore the key factors influencing their KW (kilowatt) requirements. Considering these factors, you can accurately calculate the necessary KW for your specific application.

Fluid Type and Properties

The type of fluid being heated plays a significant role in determining the KW requirements. Different liquids have distinct specific heat capacities, the energy required to raise the temperature of a unit mass of the fluid by one degree Celsius (or Kelvin). For instance, water has a specific heat capacity of approximately 4.18 kilojoules per kilogram per degree Celsius, while oil or other chemicals may have different values. The specific heat capacity affects the energy needed to achieve the desired temperature rise.

Furthermore, the physical properties of the fluid, such as viscosity and thermal conductivity, can also impact the KW requirements. Liquids with higher density or lower thermal conductivity generally require more energy to heat.

Desired Fluid Temperature Rise

The temperature rise you aim to achieve in the fluid directly affects the KW requirements. If you require a substantial temperature increase, more energy will be needed to accomplish that rise. Whether you’re looking for a slight boost in temperature or a significant jump, specifying the desired temperature rise is crucial in determining the appropriate KW.

Flow Rate and Velocity

The fluid flow rate and velocity through the system directly impact the KW requirements. Higher flow rates require more energy to maintain the desired temperature rise, as the juice spends less time in contact with the heating element. Faster velocities also affect heat transfer efficiency. So, it’s essential to consider the flow rate and speed when calculating KW requirements for your circulation heater.

Heater Efficiency and Design Factors

The efficiency and design of the circulation heater itself can affect the KW requirements. Some heaters are more efficient than others, meaning they can convert a higher percentage of input energy into heat. Higher efficiency reduces energy waste and can lower KW requirements. Additionally, design factors such as the heating element’s surface area, the vessel’s insulation, and overall system design can impact the energy required for heating.

Considering these factors, it becomes clear that accurate KW calculations require a comprehensive understanding of the fluid properties, desired temperature rise, flow characteristics, and the efficiency and design features of the heater itself.

Calculation Methodology

Now that we know the factors influencing KW requirements, let’s explore the methodology for calculating the necessary KW for your circulation heater. By following these steps, you can ensure an accurate estimation.

Determining the Specific Heat Capacity of the Fluid

The first step is determining the specific heat capacity of the fluid you’re heating. This quantity indicates the energy required to increase the temperature of a given amount of the substance by one degree Celsius (or Kelvin). Consult reliable sources or reference materials to find your fluid’s specific heat capacity value.

Estimating the Required Temperature Rise

Next, estimate the desired temperature rise for your application. Consider the starting temperature of the fluid and determine how much hotter you need it to be. This can be different depending on the specific process or application requirements. The temperature rise is usually specified in degrees Celsius or Kelvin.

Calculating the Heat Load Based on Flow Rate

To calculate the heat load, you need to consider the flow rate of the fluid. The heat load represents the amount of heat energy transferred per unit of time. Multiply the mass flow rate of the liquid (in kilograms per second) by the specific heat capacity and the temperature rise. This will give you the heat load in kilowatts.

Factoring in Efficiency and Design Considerations

Lastly, consider the circulation heater’s efficiency and design factors. If your heater has an efficiency rating expressed as a percentage, multiply the heat load by the reciprocal of the efficiency to compensate for energy losses. This adjustment ensures that the KW requirement reflects the actual energy input needed.

Additionally, consider any design factors that may affect the KW requirement. For example, if your heater has insulation or other design features that impact its efficiency, adjust the KW calculation accordingly.

By following these steps and considering the specific heat capacity, desired temperature rise, flow rate, efficiency, and design factors, you can calculate the KW requirements accurately for your circulation heater.

Example Calculation

Let’s put the methodology into practice with an example calculation. In this section, we’ll walk through a step-by-step illustration of calculating the KW requirements for a circulation heater. We’ll also provide sample values and the formulas used in the calculation.

Step-by-Step Illustration of KW Requirements Calculation

- Determine the specific heat capacity of the fluid. Let’s assume we’re heating water with a specific heat capacity of approximately 4.18 kilojoules per kilogram per degree Celsius.

- Estimate the required temperature rise. Suppose we want to raise the water temperature by 30 degrees Celsius.

- Calculate the heat load based on the flow rate. Let’s say the flow rate of the water is 100 liters per minute (l/min). Convert the flow rate to kilograms per second (kg/s) by multiplying it by the density of water (1 kilogram per liter). Calculate the heat load using the formula: Heat Load (kW) = Mass Flow Rate (kg/s) * Specific Heat Capacity (kJ/kg°C) * Temperature Rise (°C).

- Factor in efficiency and design considerations. If your circulation heater has an efficiency rating, divide the heat load by the efficiency percentage to account for energy losses.

By following these steps, you can determine the KW requirements for your circulation heater.

Sample Values and Formulas Used in the Calculation

Let’s use the following sample values for our example calculation:

– Specific Heat Capacity of Water: 4.18 kJ/kg°C

– Desired Temperature Rise: 30°C

– Flow Rate of Water: 100 l/min

– Efficiency Rating of Circulation Heater: 90%

Using the formulas mentioned earlier, we can calculate the KW requirements as follows:

– Specific Heat Capacity: 4.18 kJ/kg°C

– Temperature Rise: 30°C

– Flow Rate Conversion: 100 l/min * 1 kg/l = 100 kg/min = 1.67 kg/s

– Heat Load: 1.67 kg/s * 4.18 kJ/kg°C * 30°C = 250.74 kW

– Adjusted KW Requirement: 250.74 kW / 0.9 (90% efficiency) = 278.6 kW (rounded up)

In this example, the KW requirement for our circulation heater would be approximately 279 kW.

Following this step-by-step illustration and plugging in the appropriate sample values, you can calculate the KW requirements for your specific circulation heater application.

Selection and Sizing Considerations

Now that we’ve calculated the KW requirements for your circulation heater, it’s essential to understand how to select and size it appropriately. This section discusses the considerations in matching the heater capacity to the KW requirements, the implications of oversizing and under-sizing, and safety factors and recommendations.

Matching Heater Capacity to KW Requirements

When selecting a circulation heater, choosing one that matches the calculated KW requirements is crucial. Ensure that the heater’s capacity aligns with the determined KW value. Selecting a heater with a lower capacity can result in inadequate heating, while choosing a higher degree than necessary can lead to energy wastage and increased costs.

Over-sizing and Under-sizing Implications

Over-sizing and under-sizing circulation heaters can have significant implications. Over-sizing or selecting a heater with a higher-than-required capacity can lead to excessive energy consumption and unnecessary costs. It may also result in reduced efficiency and potential operational issues.

On the other hand, under-sizing, or choosing a heater with a capacity lower than required, can lead to insufficient heating. This can impact the performance of your system, potentially causing delays, decreased productivity, or compromised quality in your processes. It’s crucial to avoid under-sizing to ensure optimal operation and desired results.

Safety Factors and Recommendations

When selecting and sizing your circulation heater, it’s essential to consider safety factors and follow manufacturer recommendations. Ensure the heater is designed and rated to handle your application’s specific fluid and operating conditions. Consider factors such as pressure, temperature limits, and other safety guidelines the manufacturer provides.

Also, consult with experts or manufacturers to understand any additional safety measures or recommendations for your industry or application. This may include features like temperature control devices, pressure relief valves, or insulation requirements to ensure safe and efficient operation.

By carefully matching the heater capacity to the KW requirements, avoiding oversizing or under-sizing, and adhering to safety factors and recommendations, you can ensure your circulation heater’s optimal selection and sizing.

Conclusion

In conclusion, accurately calculating the KW requirements for your circulation heater is vital for efficient and effective heating. Let’s recap the key points and highlight the importance of accurate KW calculations.

Accurate KW calculations ensure your circulation heater is appropriately sized to meet your heating needs. By considering factors such as the fluid type and properties, desired temperature rise, flow rate and velocity, and efficiency and design considerations, you can determine the precise KW requirements.

Remember, accurate KW calculations are just one piece of the puzzle. Consult with experts or manufacturers for guidance tailored to your unique circumstances. They can provide insights and recommendations and assist you in selecting the most efficient and effective circulation heater for your needs.

If you want to know the industrial applications of circulation heaters, click here.