Do you need to set up a flanged heater but aren’t sure where to start? Flanged immersion heater is important for heating liquids and gases in many industries, and getting them installed and working properly is key.

In this beginner’s guide, we’ll walk you through everything you need to know about installing, wiring, and maintaining flanged heaters. We’ll keep things simple so you can feel confident in handling these tasks. Let’s get started!

What are Flanged immersion Heaters?

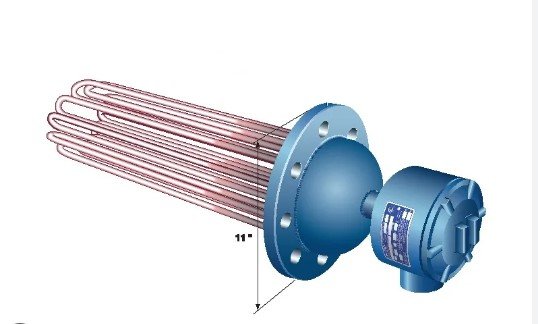

Flanged immersion heater, such as the FH Series, are robust heating elements designed for efficient heat transfer in various applications. They come with “U” bend tubular heating elements, which are welded into a standard ANSI pipe flange. These flanged heaters are supported by TEMA-style baffles, ensuring stable positioning and effective heat distribution. A key feature is the thermowell installed through the center of the flange, which houses an over-temperature sensor to prevent overheating.

These flanged immersion heaters come equipped with a NEMA-rated enclosure that protects the heater element terminations and pre-bussed circuitry. The enclosure also allows for custom placement of conduit knock-outs for field wiring, accommodating various installation needs. Capable of heating a wide range of media—including water, air, steam, gas, light and heavy oils, thermal fluids, and chemicals—these heaters can operate at temperatures up to 1,200°F, depending on the medium. This versatility makes them suitable for diverse industrial and commercial applications.

What You Need to Know About Flanged immersion Heater Installation?

Installing Flanged immersion heating element can be straightforward if you follow these essential steps and guidelines:

Positioning the Heater

When installing a flange immersion heater, ensure that the heated liquid can cover the flanged immersion heater. This coverage is crucial for proper heat transfer and to avoid overheating. Avoid placing the flanged heater too low in tanks where sludge might accumulate, as this could cover the heater and lead to overheating or premature failure of the heating elements.

Proper Placement for Heat Transfer

For optimal performance, place the heated section of the flanged heater deep enough inside the tank to ensure efficient heat transfer. In large tanks, it is better to use multiple smaller flanged heaters instead of a single large one. This approach helps distribute heat more evenly and avoids high watt density in one spot, which can improve overall heating efficiency.

Install Controls and Safety Devices

Ensure that your installation includes adequate controls and safety devices. These are essential to prevent excessive temperature and pressure build-up, which can damage the flanged heater or create safety hazards. Proper controls will help maintain a stable operating environment and extend the life of your heater.

Prepare the Gasket Surface

Before installing the Flanged immersion heater clean and dry the gasket surface thoroughly. A clean surface is crucial for creating a good seal and preventing leaks. Ensuring the surface is dry will also help avoid any issues related to moisture that could compromise the heater’s performance.

Voltage Compliance

Do not operate the Flanged immersion heatert at a voltage higher than what is specified on the unit. Running a heater at a higher voltage can damage it or cause safety issues. While you can run the flanged immersion heater at a lower voltage, this will reduce its output wattage, so ensure you adjust according to your heating needs.

Follow Wiring Instructions

A wiring diagram is provided in the electrical enclosure of the flanged immersion heater. This diagram is essential for proper electrical connections. The heater circuits are labeled to help with correct wiring. Make sure to follow these diagrams closely to avoid any wiring mistakes that could affect the heater’s performance.

Secure Electrical Connections

Ensure that all terminal connections are tightened properly using a wrench or screwdriver, with torque suitable for the terminal strength. Use a backup wrench to prevent twisting the Flanged immersion heating element terminals while tightening. Regularly check that electrical connections remain clean and tight to ensure safe and efficient operation.

Insulation Resistance Check

Electric heater insulation can absorb moisture from humid environments, shipping, or long periods of inactivity. This moisture can reduce insulation resistance and lead to heater failure. Use a megohmmeter to check insulation resistance before powering the flanged immersion heater. If moisture is detected, bake the heater at approximately 350°F (176.7°C) to expel the moisture and restore insulation resistance.

Thermostat Use

If your Flanged immersion heating element comes with an integral thermostat, remember that it serves as a temperature control device but is not a fail-safe mechanism. The thermostat helps regulate temperature but should be used in conjunction with other safety measures to ensure reliable operation.

Click here to learn more about how to select immersion heaters.

Essential Tips for Wiring Flanged immersion Heaters Safely

Here, we have compiled essential tips for wiring flanged heaters safely. Whether you’re a beginner or need a refresher, these guidelines will help ensure a safe and efficient wiring process.

Safety First

Before starting the installation or servicing of the flanged heaters, always disconnect all power to avoid the risk of electric shock. This is crucial for your safety and to prevent potential damage. Only qualified professionals should handle the installation, following the National Electrical Code (NEC) and NFPA 70 standards to ensure everything is done correctly.

Use Copper Conductors

When wiring the flanged heater, use only copper conductors. This is a requirement to ensure safe and efficient electrical connections. The wiring must be installed according to the National Electrical Code and local regulations by a qualified electrician.

Avoid Series Connections

Do not connect heaters in series if their element wattages differ. Series connections can lead to uneven heating and potential damage to the heaters. Each heater should have its own direct electrical supply.

Protect Wiring from Corrosion

Electrical wiring should be housed in rigid conduit or sealed flexible conduit to protect it from corrosive vapors and liquids. If the installation is in a high-humidity area, ensure the conduit slopes away from the heater to prevent moisture from entering the conduit.

Use Watertight Connectors for Flex Cords

If you use flexible cords, ensure that a watertight connector is used where the cord enters the terminal enclosure. For outdoor installations, use liquid-tight conduit and connectors to keep moisture and contaminants out of the electrical connections.

Install Power Line Wires

Bring the power line wires through the opening in the heater’s terminal box. The heater should be pre-wired and tagged to assist with the correct electrical connections. Refer to the heater’s specific wiring diagrams and tags for guidance.

Check and Tighten Connections

Examine all terminal connections for any looseness and tighten them as necessary. Made-to-order heaters are pre-wired and tagged at the factory, but wiring might differ from standard diagrams. Always verify the voltage and phase on the heater’s nameplate and use the appropriate wiring diagram provided in the terminal enclosure.

Ensure Correct Wire Capacity

The power supply leads should have a current-carrying capacity that exceeds the heater’s amperage by at least 25%. Consider the ambient operating temperature and adjust the wire’s ampacity rating accordingly. Heaters with the same voltage and wattage can be connected in series for higher voltage operation, but ensure that all connections comply with safety standards.

How to Keep Your Flanged immersion Heaters in Top Shape: Essential Maintenance Tips

Let’s have a look at the maintenance tips below to keep your flanged heaters running smoothly and efficiently.

Regular Inspections and Cleaning of immersion heater

Consistently check your flanged immersion heater for any signs of coating, corrosion, or sediment build-up. Regular cleaning helps prevent these issues from reducing the heater’s efficiency and lifespan. Ensure that both the heater and the tank are free from sludge and debris, which can insulate the heater and cause overheating.

Tighten Terminal Connections of immersion heater

Inspect and tighten all terminal connections periodically to prevent electrical problems. Loose connections can cause arcing, overheating, and eventual heater failure. Always use a backup wrench when tightening connections to avoid damaging the terminals.

Protect Against Corrosion and Moisture of immersion heater

If there is corrosion on the terminal housing of the heater, check and replace the gaskets if necessary. Ensure that the conduit layout is such that moisture cannot enter the enclosure, as moisture can degrade the electrical insulation and lead to heater failure.

Check Sheath Material and Compatibility of immersion heater

Verify that the heater’s sheath material matches the heated medium. For instance, copper-sheathed elements can be used for oils, and stainless steel for water or corrosive solutions. Consult with the manufacturer if you are unsure about the appropriate material for your specific application.

Monitor Thermostat Settings and Watt-Density of immersion heater

Keep thermostats set below the boiling point of the liquid to avoid overheating and steam pockets. Also, make sure the wattage density of the heater is appropriate for the material that needs to be heated to avoid overheating and inefficiency. Regularly review these settings to maintain optimal heater performance.

Where to Find the Best Deals on Flanged immersion Heaters?

Looking for the best flanged heaters and expert support for your installation and maintenance needs? HASTECO is the go-to choice. With over 30 years of experience, HASTECO excels in providing top-notch flanged heaters and comprehensive support for every step of your project.

From helping with installation to ensuring proper wiring and maintenance, their experienced team uses advanced project management tools to keep everything on track. They handle everything from technical reviews to risk analysis, ensuring high standards in quality, delivery, cost, and features.

HASTECO’s commitment to quality is evident in their thorough inspection and manufacturing processes. If you want reliable flanged heaters and expert guidance throughout installation and maintenance, HASTECO is the trusted name to choose.

Bottom Line!

Now that you have the basics of flanged heater installation, wiring, and maintenance, you’re ready to handle these tasks with confidence. Remember to follow the steps carefully and keep safety and regular upkeep in mind to ensure your flanged heater works efficiently. If you’re looking for high-quality heaters, check out HASTECO Technologies for their top-notch collection. We hope this guide has been helpful—stay tuned for more useful tips and information.